Vinyl Ester Toughness

The increase of algae particulate in vinyl ester matrix increases the fracture toughness values.

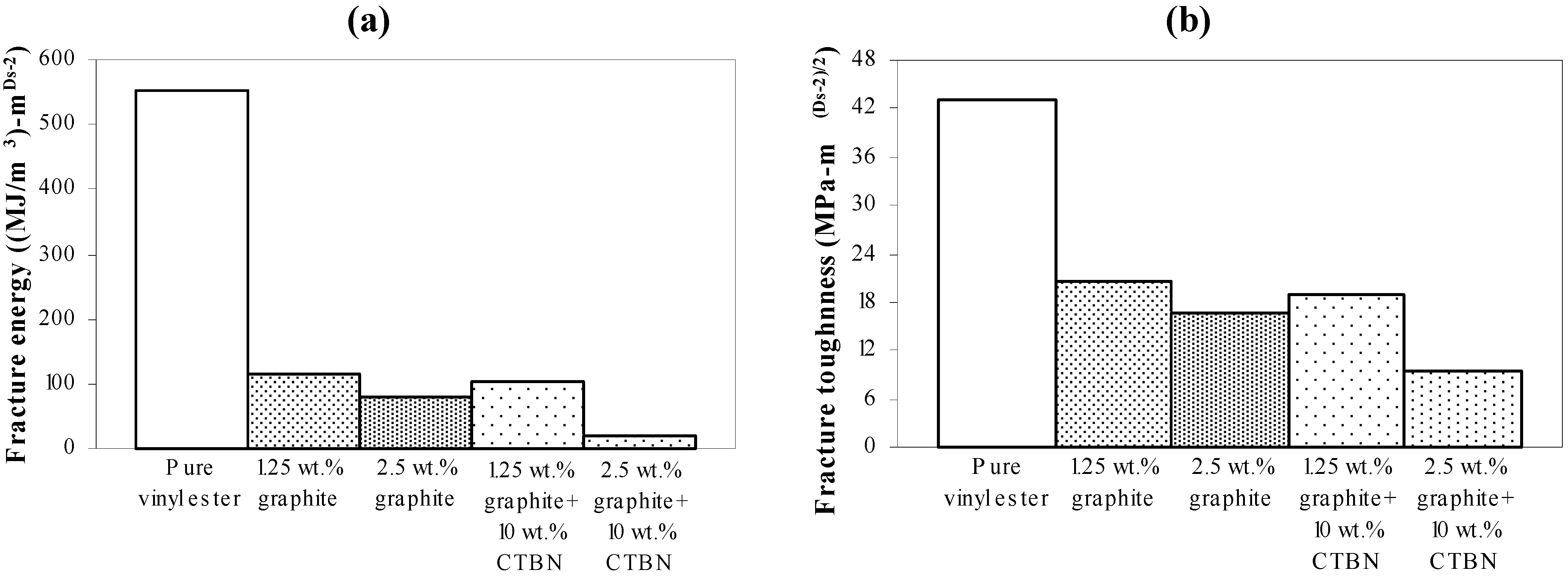

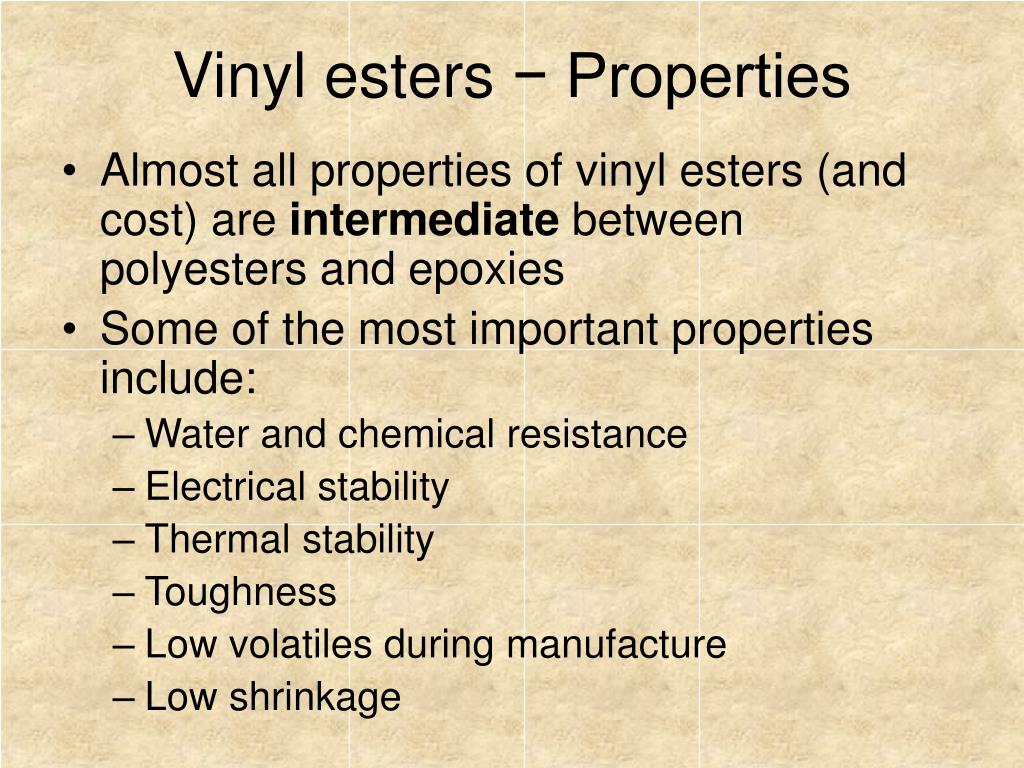

Vinyl ester toughness. The fracture toughness of vinyl ester composites varies slightly. The fracture toughness of neat vinyl ester resin 27 15 mpa 𝑚 is expected to be much higher than its counterpart 8 43 mpa 𝑚 because the former is a higher class resin with higher cost. For vinyl ester resins with longer lengths mn 1000 g mol crosslinked networks have higher fracture toughness values and lower tg s. Because of this they are typically used when high durability thermal stability and extremely high corrosion resistance are needed.

Their longer double bonded vinyl groups that link the ester groups together contribute a flexible nature to the resin. Plane strain fracture toughness astm d5045 single edge notch bending senb k 1c and g 1c. Vinyl ester resins. This paper presents the analysis of the fracture of the samples using a scanning electron microscope sem.

The results show that the difference in the fracture toughness is minimal 4. Vinyl ester resins actually exceed both polyester and epoxy in corrosion resistance temperature resistance and elongation toughness. The k ic values of the epoxy and vinyl ester ranged from 0 64 to 2 66 mpa m 1 2 and from 0 22 to 1 75 mpa m 1 2 respectively in the cycled composites. Vinyl esters are halfway between polyesters and epoxies as far as typical properties and toughness and they are a step up on a cost basis.

The composite specimen with 25 volume fraction of algae filler exhibited good fracture toughness value. Since the impact strength of the vinyl ester composites cured under microwave conditions had been proved to be as good as their counterparts the fracture toughness of the two groups of composites are therefore compared. They offer excellent toughness and fatigue resistance. Table 1 shows the average k ic values of the epoxy and vinyl ester composites with cyclic times of wetting and drying.

They are based on bisphenol a epoxy resin and they provide resistance to a wide range of acids alkalis bleaches and solvents for use in many chemical processing applications. It is due to uniform dispersion of algae particulate with vinyl ester resin material. Cured vinyl ester particulate composites and those cured under ambient conditions.