Vinyl Ester Resin Mixing Ratio

Resin has a short shelf life.

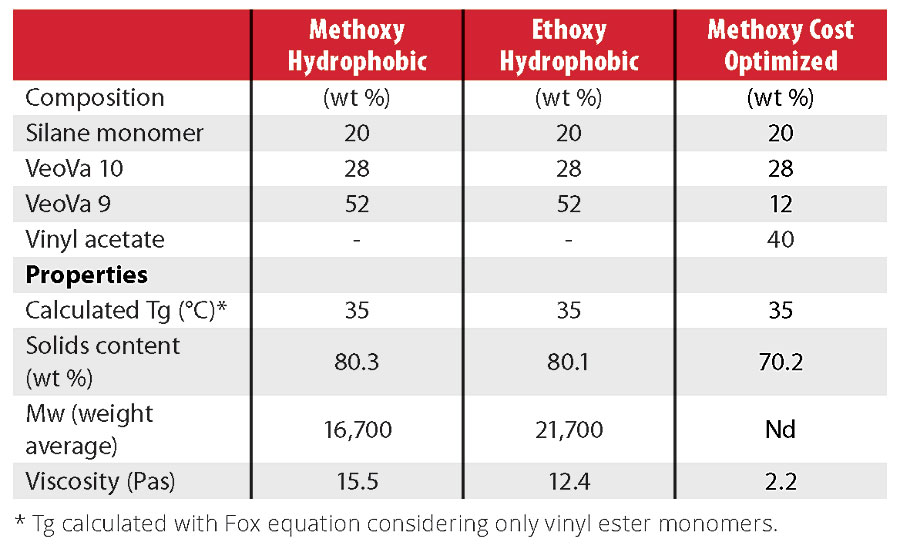

Vinyl ester resin mixing ratio. These resins only require about 1 5 catalyst and are quite specific on the ratios especially in hot weather. Methyl ethyl ketone peroxide mekp is an organic peroxide used in the marine industry. The speed of hardener chosen depends. Vinyl ester resin derakane momentum 411 350 epoxy vinyl ester resin is based on bisphenol a epoxy resin and provides resistance to a wide range of acids alkalis bleaches and organic compounds for use in many chemical processing industry.

Cc cubic centimeter. Vinyl ester resin is considered a hybrid of polyester and epoxy meaning its handling characteristics properties and price generally fall just between the other two. Using drops for catalyst measurement is only an estimate. 30 drops is approximately equal to one cc.

Gelcoat and polyester resin including boatyard use a standard catalyst or the 925 catalyst. Oz fluid ounce. The styrene in the polyester or vinyl ester resin will melt it. Vinyl ester resins and polyester resins are very close in molecular composition.

Vinyl ester has a shelf life of 3 months. Mix ratio is 1 2 filler to resin by volume for general use 1 3 filler to resin by volume to reduce runs sagging. Try to store the resin in a cool dry place or refrigerate do not freeze it to extend the life of the resin. There is a choice of three different hardeners.

Vinyl ester resins and polyester resins are very close in molecular composition. Catalyst chart for polyester resin gel coat and vinyl ester marine resins. The difference is that the molecular chain is longer in vinyl ester resin. Add filler after adding catalyst to resin.

You can mix it 1 to 2 by weight. Our epoxy resins come in either a 2 1 or 4 1 mixing ratio. One gallon of polyester resin weighs approximately 9 2 lbs. It is important to note that of the three vinyl ester resin will provide the highest corrosion resistance temperature resistance and elongation toughness.

One gallon of gelcoat weighs approximately 10 5 lbs. Epoxy resin should be used. The mix ratio is by volume. Fast medium and slow.

Mixing the correct ratio of a b is extremely important. The molecular chain is longer in vinyl ester resin. The weight of mekp 925 is 1 125 grams per cc. You will also see vinylester requires a ratio of 2 by volume as opposed to gelcoats and resin which are closer to 1 5.

Most problems that occur with improper cure is due to not measuring the correct ratio or not mixing completely the two components.