Vinyl Ester Resin Hardener Ratio

One gallon of gelcoat weighs approximately 10 5 lbs.

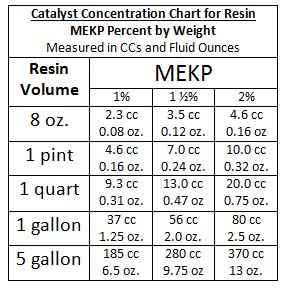

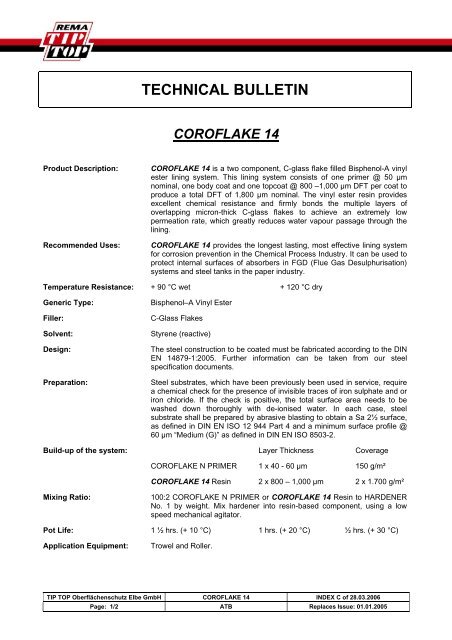

Vinyl ester resin hardener ratio. Vinyl ester resin is selected due to its well known performance in marine conditions and good chemical resistance to a wide range of chemicals including sour crude up to 100 c. To cover wood a laminate using epoxy resin and 10 oz cloth will yield a much better job than 10 oz. Catalyst chart for polyester resin gel coat and vinyl ester marine resins. Cloth and polyester resin.

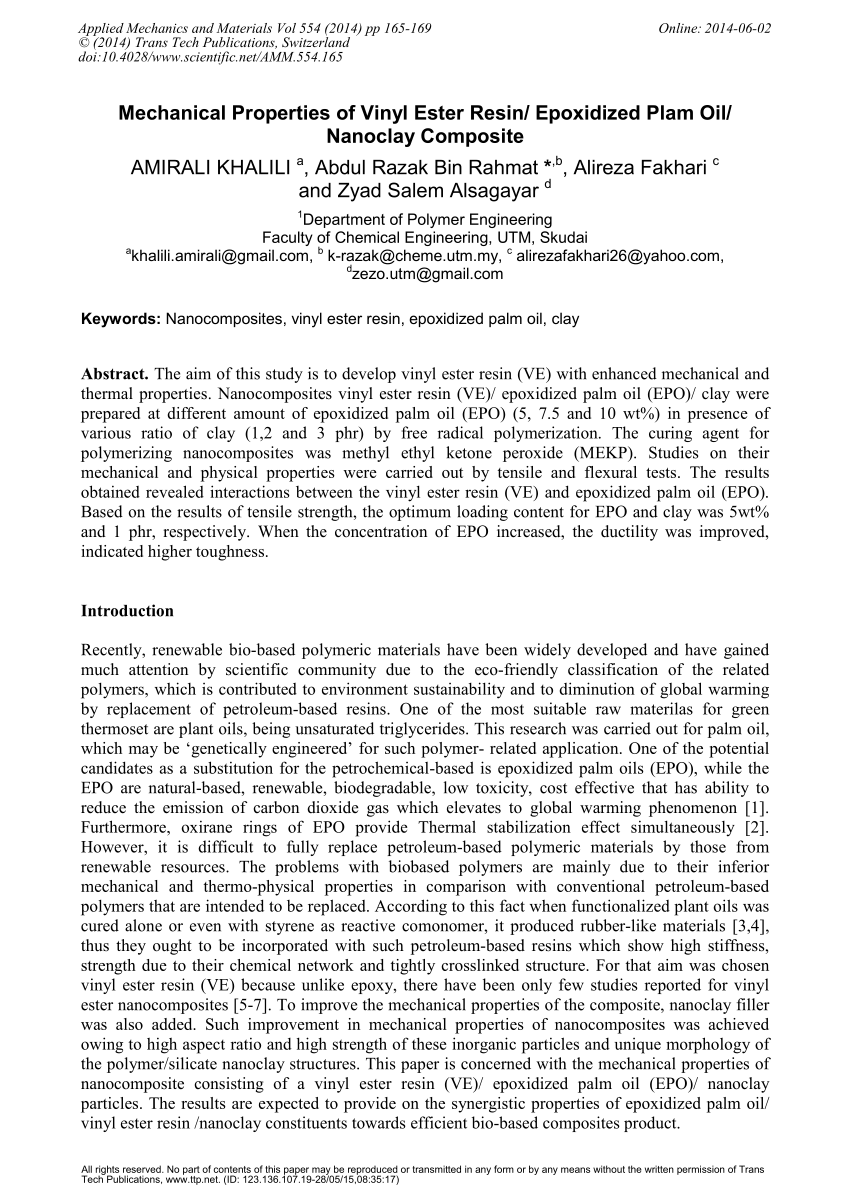

Vinyl ester resin cures with a tack. Try to store the resin in a cool dry place or refrigerate do not freeze it to extend the life of the resin. Ve resin is a tougher resin because of its longer molecular chains. An mekp catalyst is mixed with polyester vinyl ester resin in a very low ratio just a few drops of catalyst per ounce of resin.

It has a measured glass transition temperature t g of 110 c hence allowing the clamp to withstand up to a maximum service temperature of 80 c. The styrene in the polyester or vinyl ester resin will melt it. Vinyl ester has a shelf life of 3 months. It can withstand repeated bending better than both polyester and epoxy resin.

The speed of hardener chosen depends on the temperature in the. Fast medium and slow. Epoxy resin should be used. Catalyze 1 5 get a pint for a.

Our epoxy resins come in either a 2 1 or 4 1 mixing ratio. Mekp is also used with gel coats. One gallon of polyester resin weighs approximately 9 2 lbs. The hardener catalyst for vinyl ester resin and polyester.

It wets out glass very quickly and has low viscosity. The hardener catalyst for vinyl ester resin is mekp methyl ethyl ketone peroxide. Oz fluid ounce. You can vary the cure time for polyester vinyl ester resins by reducing or increasing the.

Epoxy adheres to wood much better than polyester does. It is the same catalyst used with polyester resins. When using vinyl ester resin be sure to use it quickly after purchasing. The weight of mekp 925 is 1 125 grams per cc.

Methyl ethyl ketone peroxide mekp is an organic peroxide used in the marine industry. Regarding costs vinyl ester resin is more expensive than polyester resin but cheaper than epoxy resin. Epoxy resin uses a hardener and polyester vinyl ester resins use a catalyst usually mekp methyl ethyl ketone peroxide. Mekp is the catalyst hardener needed to cure polyester and vinyl ester resins.

It adds excellent strength rigidity adhesion water and chemical resistance. So if you need vinylester and you have a vertical surface you might consider the reichhold hydrex 100 products. 30 drops is approximately equal to one cc. It is a solution of methyl ethyl ketone peroxides and cumyl hydroperoxide in phlegmatizer.

There is a choice of three different hardeners. Using drops for catalyst measurement is only an estimate. Hetron 922 l25 vinylesterhetron 922 l25 vinylesterashland s hetron 922 l25 is an incredibly versatile resin. Resin has a short shelf life.

It is meant for a room temperature cure.