Vinyl Ester Infusion Resin

Infusion vinyl ester 5 gallons.

Vinyl ester infusion resin. Comes pre promoted with dma only you will need to add cobalt to suit your application. Vinyl ester resin is considered a hybrid of polyester and epoxy meaning its handling characteristics properties and price generally fall just between the other two. Rdr 3121 rdh 9386 99 high impact high temp vacuum infusion epoxy 3 1 1 33 gallon kit 325 f 1 hour pot life kit size 1 33 gallon. Vinyl ester resins are the binary resin systems containing a dimethacrylate monomer from which the cured material gains most of its properties and a reactive monomer such as styrene which acts as a reactive diluent and also takes part in the cross linking reaction.

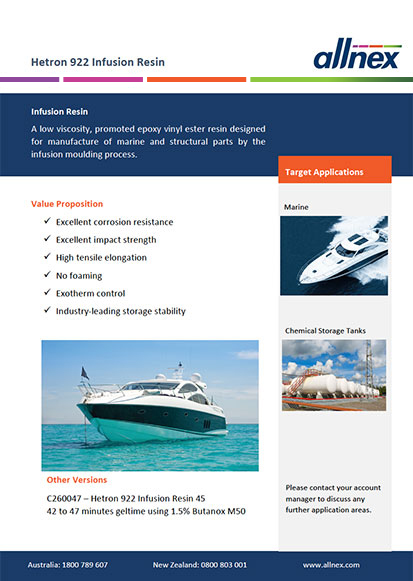

This vinylester infusion resin is a low viscosity corrosion resistant resin for use in various applications where added strength and heat resistance are needed but without the cost of an epoxy. Contact us for more information. Historically vacuum infusion of thick laminates has been avoided because of the likelihood of uncontrolled or runaway exotherm. Corve8100 50 is manufactured from ingredients listed as acceptable in the fda code of federal regulation title 21 cfr 177 2420.

But this 5 375 inches 135 mm thick fiberglass vinyl ester hatch cover for a flue gas desulfurization installation was successfully produced by kenway corp. It is important to note that of the three vinyl ester resin will provide the highest corrosion resistance temperature resistance and elongation toughness. Consequently they are generally cut in styrene monomer for management as a liquid resin. It s heat resistant and blended for durability.

A nonpromoted low viscosity corrosion resistant vinyl ester resin for use in vacuum infusion and rtm applications. Augusta maine using a resin modified with new initiator chemistry developed by arkema philadelphia pa. Vinyl ester is formulated for maximum corrosion resistance to most fuels vapors and chemicals. Infusion vinyl ester resin 5 gallons features great physical properties and low viscosity for infusing.

Normal viscosity for vinyl esters is less than polyester about 500 centipoise when cut in styrene monomer. Advances in fire retardant materials 2008.