Vinyl Ester Coating Boat

Can be pigmented 2oz 8oz per gallon hazardous shipping charge applies to 5 gallon pails.

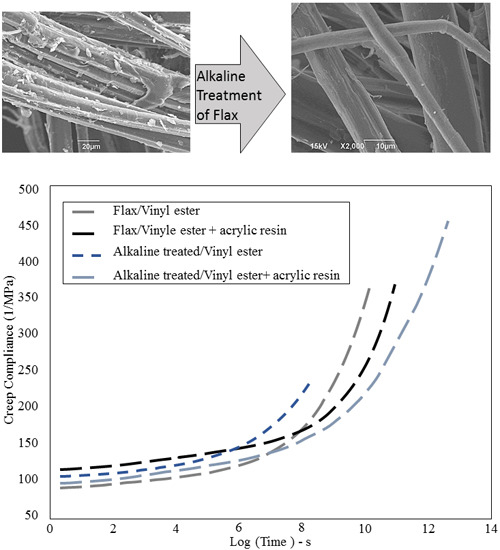

Vinyl ester coating boat. Still barrier coats have remained popular. Essentially they comprise a base of polyester resin strengthened with epoxy molecules in the backbone of the molecular chain. In terms of physical properties and cost vinylester resin is a compromise between low cost polyesters and epoxy resins. Vinyl esters also use peroxides e g.

Product promoted at time of sale all sales are final. It is a highly chemical resistant resin that provides excellent resistance to alkalis acids and a broad range of chemicals. The reason for this preference is that vinyl ester resins have a higher chemical mechanical and above all thermal resistance. Prices include mekp hardener.

Technical characteristics and properties of gelcoat vinyl ester. Vinyl ester flake lining coating pip ve cr 40 flake is a 40 mil catalyzed vinyl ester resin for medium duty protection of steel or concrete substrates. Most boatbuilders have embraced vinyl ester or epoxy resin either for the entire hull or as a skin coat. The coating system can achieve a dry film thickness of up to 1350 microns 54 mils in a single coat.

For any new boat that doesn t utilize one of the blister resistant resins an exception to the rule these days barrier coats are a. Its use is limited to the construction of high performance power boats where vinylesters increased bond strength has helped eliminate bonding problems with core materials vinylester resin is also used as a great water barrier when mixed properly with glass. A two component modified epoxy vinyl ester or vinyl ester novolac based primer. Hull bottom coating for trailerable boats and commercial boat decks fuel tank coating.

Corobond vinyl ester primer. Vinyl ester resins are produced by the reaction esterification between an epoxy resin and an unsaturated monocarboxylic acid. It is used for steel or concrete tank linings in immersion service. Designed to promote adhesion to concrete and metal substrates corobond vinyl ester primers also resists mechanical stresses such as impact tensile and flexural stress.