Unvented Roof Insulation

Senior engineer manager at icynene john broniek makes the case for the unvented attic assembly and why insulating the underside of the roof makes sense.

Unvented roof insulation. Four options for building an unvented roof assembly. We agree that avoiding sheathing rot is critical and that air permeable insulation such as fiberglass or cellulose cannot be used alone. In this post we will show that while the propink unvented insulation system may provide a safe roof in zones 2b 3b if we instead combine dense fiberglass insulation batts or densepacked with intello smart vapor retarder and airtight membrane we can make safe and robust unvented roofs in climate zone 6. Over the past five years several unvented roof insulation systems have been developed by the building science consortium for use primarily in hot dry and hot humid climate zones.

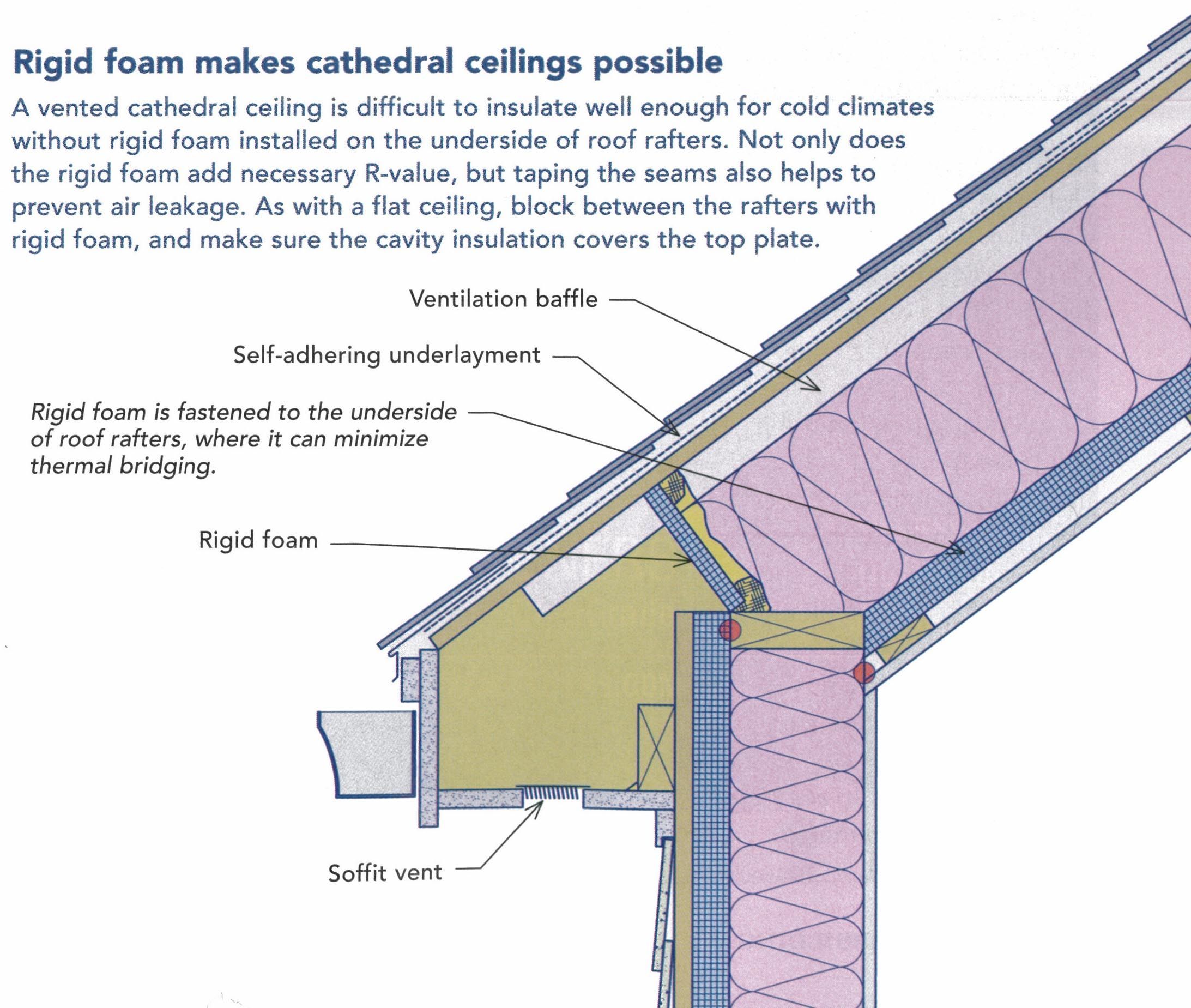

This piece originally the quest for greater energy efficiency in buildings has led to increasing interest and need for insulation improvements in hvac equipment more airtight construction new materials and assemblies. Insulation and air barrier are applied directly to the underside of the roof deck are common in applications where designers are seeking cost effective and energy efficient roof assemblies. Unvented roof assemblies should be insulated either with air impermeable insulation rigid foam or spray polyurethane foam or with a combination of foam and air permeable insulation. Designs and houses with unvented roof insulation systems have also been developed and constructed in cold and mixed climates.

In the most recent issue of fine homebuilding martin holladay wrote a piece on insulating unvented roof assemblies. But in it unfortunately all four options provided are dominated by foam.